Committed To Quality, Committed To You

An ingenious machine that allows you to screen difficult materials with ultrasonic frequencies, the Ultrasonic Sivtek is a one-of-its-kind sieving machine that is quickly transforming the way we process our raw materials. It allows you to effortlessly break down hard & difficult dry materials, which expands the range of materials that you can screen.

Powered by a specially designed transducer, the Ultrasonic Sivtek uses ultrasonic frequencies to alter the surface tension of the materials, which easily breaks the bonds between molecules and crumbles dry substances.

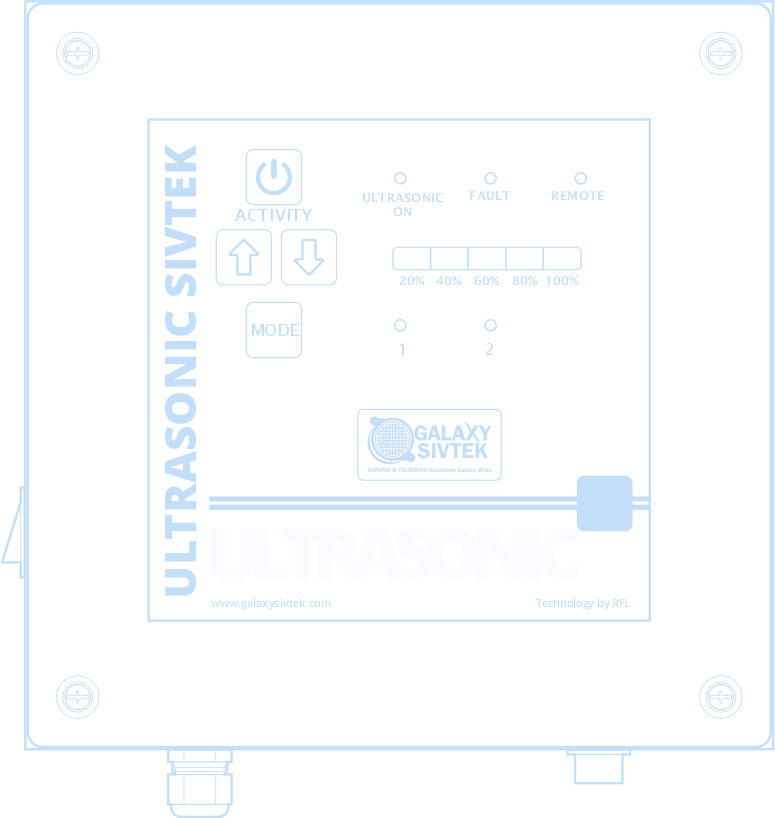

The Ultrasonic Sivtek works on a 100W power system and allows you to monitor the frequency and temperature fault conditions. This gives you a heightened level of control over the screening process, which allows you to calibrate the result according to your requirements. It can also allow accurate separation down to 20µ.

Furthermore, as the machine uses ultrasonic frequencies to break down the materials, there is no movement of the screens or the machine. The robust design of the machine also allows it to continuously function for extended hours, without taking a break.

With this robust and innovative method of screening dry products, various industries and companies have been able to substantially increase their production rates and have become able to meet the screening specification more accurately. Moreover, they have also been able to extend their screen life, as the machine involves minimal screen movement.

The ingenious design of the Ultrasonic Sivtek accommodates acoustically coupled components around the mesh surface that transport ultrasonic frequencies which are generated from a specially designed piezo transducer. The signals that are sent to the transducer are controlled in amplitude, frequency, and phase.

Ultrasonic vibrations continuously clean the mesh surface, preventing choking, clogging, and material build-up during fine and ultra-fine screening.

Enables consistent separation of ultra-fine dry and agglomerated materials without affecting particle integrity.

Unlike conventional vibration methods, ultrasonic energy acts directly on the mesh surface, minimizing wear and ensuring stable screening performance.

Designed to be easily integrated with existing sieving machines of any brand (18”–60”), without structural modification or extended downtime.