How Galaxy Sivtek Helped a Customer Achieve Greater Efficiency in Tapioca and Maize Starch Production

Client’s profile:

India’s biggest manufacturer of Tropic starch and maize starch useful for multiple industries such as food processing, pharmaceutical, paper, textile, adhesives, etc. The customer has multiple processing plants all across the South India. They also export the starch to other south Asian countries.

About the product:

Tapioca starch and maize starch have various uses across several industries. Here are some examples:

Uses of Tapioca Starch:

- Food Industry: Tapioca starch is used as a thickener, binder, and stabilizer in a wide range of food products such as soups, sauces, gravies, baked goods, and noodles. It is also used as a gluten-free alternative to wheat flour in some recipes.

- Pharmaceutical Industry: Tapioca starch is used as an inactive ingredient in the production of drugs and tablets.

- Textile Industry: Tapioca starch is used as a sizing agent in the textile industry to improve the weaving properties of the fabric.

- Paper Industry: Tapioca starch is used as a binder and coating agent in the paper industry to improve paper quality and strength.

These are just a few applications amounts many other.

Challenges:

The customer faced multiple challenges with their existing production plant and machines. Firstly, their current machines were not achieving the desired efficiency. Secondly, despite having 4 different centrifugal sifters, they were not able to achieve the required output from the 4 European-made sifters. Thirdly, the wire mesh basket had to be replaced frequently due to it tearing repeatedly.

Moreover, the customer had a specific requirement to integrate the new machines into their current plant layout while ensuring enhanced efficiency and productivity. This posed an additional challenge, as the machines had to be customized to meet the specific requirements of the plant layout. Finally, the machines had to meet the hygienic standards required for supply to the food and pharmaceutical industries. This meant that the materials used in the machines had to be food-grade and easy to clean, with minimal risk of contamination.

Solution

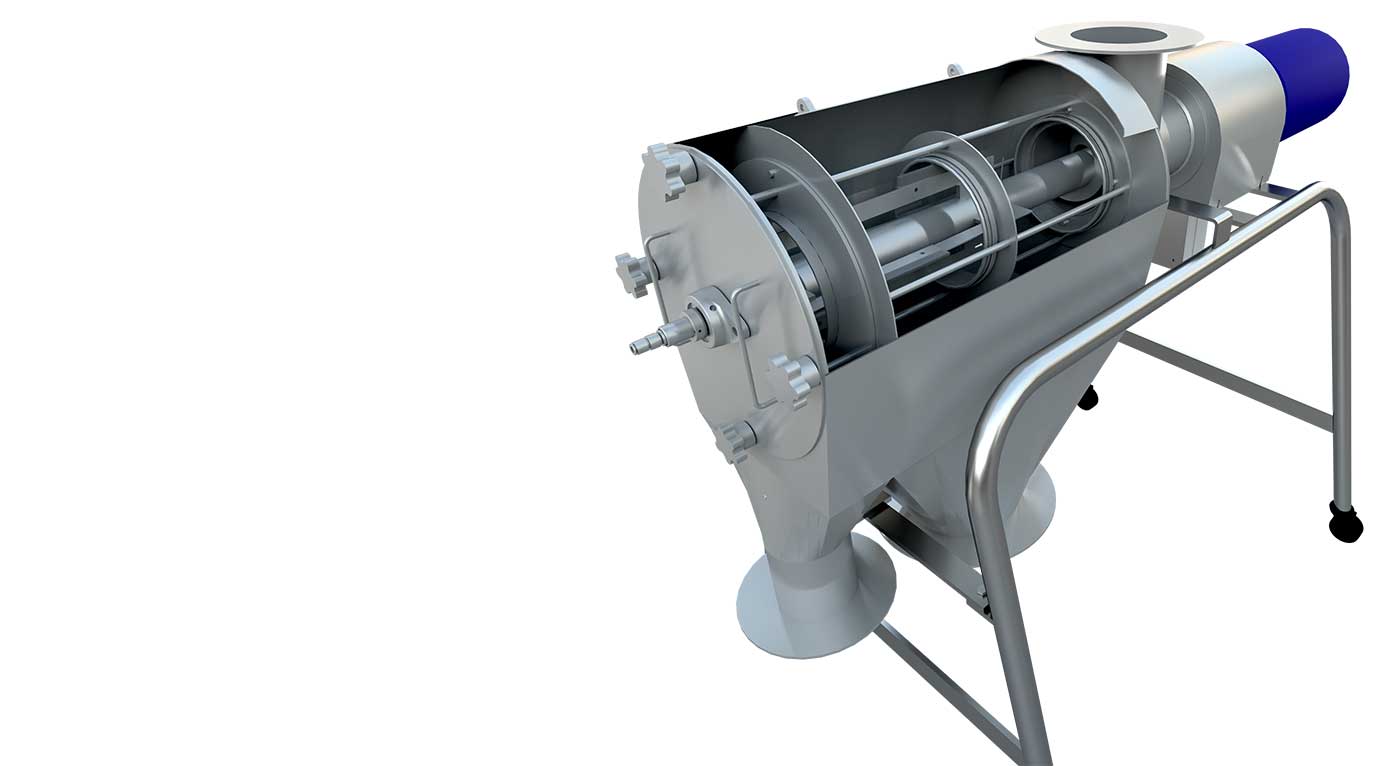

Experts from the Galaxy Sivtek visited the customer production facility and Galaxy Sivtek provided the Roto 1350, which is a high-capacity centrifugal sifter with advanced features to overcome the challenges faced by the customer.

Firstly, the Roto 1350 is designed to achieve high efficiency levels, making it an ideal solution for the customers productivity concerns. It operates at a higher speed, which enables it to achieve a greater throughput than traditional sifters, reducing the time and resources required for the screening process.

Secondly, with the Roto 1350, the customer no longer had to use multiple sifters to achieve the desired output. The machine has a large surface area, which enables it to sieve a higher volume of material with ease. Additionally, the Roto 1350 is equipped with advanced technologies that allow it to perform precise screening, ensuring that all contaminants are removed from the product.

Thirdly, the Roto 1350 is equipped with a durable, stainless steel mesh screen, eliminating the need for frequent mesh replacement, which had been a recurring issue for the customer. This resulted in significant cost savings and reduced downtime for the customer.

Fourthly, the Roto 1350 was custom designed to fit seamlessly into the customer’s existing plant layout. It was installed and commissioned by the Galaxy Sivtek team, ensuring that the machine delivered the desired output and efficiency levels while being integrated into the customer’s production line.

Lastly, the Roto 1350 is made of high-quality materials and is designed to meet strict hygienic standards, making it suitable for use in the food and pharmaceutical industries. It ensures that all contaminants are removed from the product and eliminates the risk of product recalls, ensuring that the customer’s products meet the highest quality standards.

Overall, Galaxy Sivtek’s Roto 1350 provided a comprehensive solution to the customers challenges, enabling them to achieve higher efficiency levels, increased productivity, reduced maintenance costs, and improved product quality.

Results

As a result of our efforts, the customer achieved a significant increase in output, with a single Roto 1350 machine producing 3.5 tons instead of the previous four machines. To address their needs for different sieving sizes, we provided three different wire mesh basket configurations. We also supplied all the necessary parameters for manufacturing tropical and maize starch, ensuring the final product met the standards required for various industries in both national and international markets.