Success story of coffee powder with zero production loss

Overview

One of the world’s leading FMCG company having a global presence with multiple plants across 190 countries were looking for an active screening solution for one of their many consumable products i.e. Coffee Powder.

The production head of the unit came to know about Galaxy Sivtek’s solution with internal reference only as they were already using our machines for their different products such as detergent powder & more.

Requirement & Challenges

One of our Sales engineers was invited for an initial meeting to discuss what problem they were facing with their current sieving machine & what was the best solution for the same.

During the technical meet up the Production Head stated a real-time problem. The main problem was of 5% to 10% of material loss, which indirectly increased their reprocessing time & cost.

They were currently using round vibro sifter of other brands.

Coffee powder forms lumps due to the presence of moisture; now while screening in round Vibro sifters lumps are removed as oversize material from outlet. They did not want to go coffee powder lumps in waste as it was the formation of coffee powder only.

Also, the company is one of the largest & biggest FMCG in the world, were bond to certain guidelines to make sure working environment is Human Friendly. Current Vibro Separators were generating too much noise & that was not good for the workers. The Production Head also stated that they want a screening machine that operates at minimal noise & without vibration.

Solution

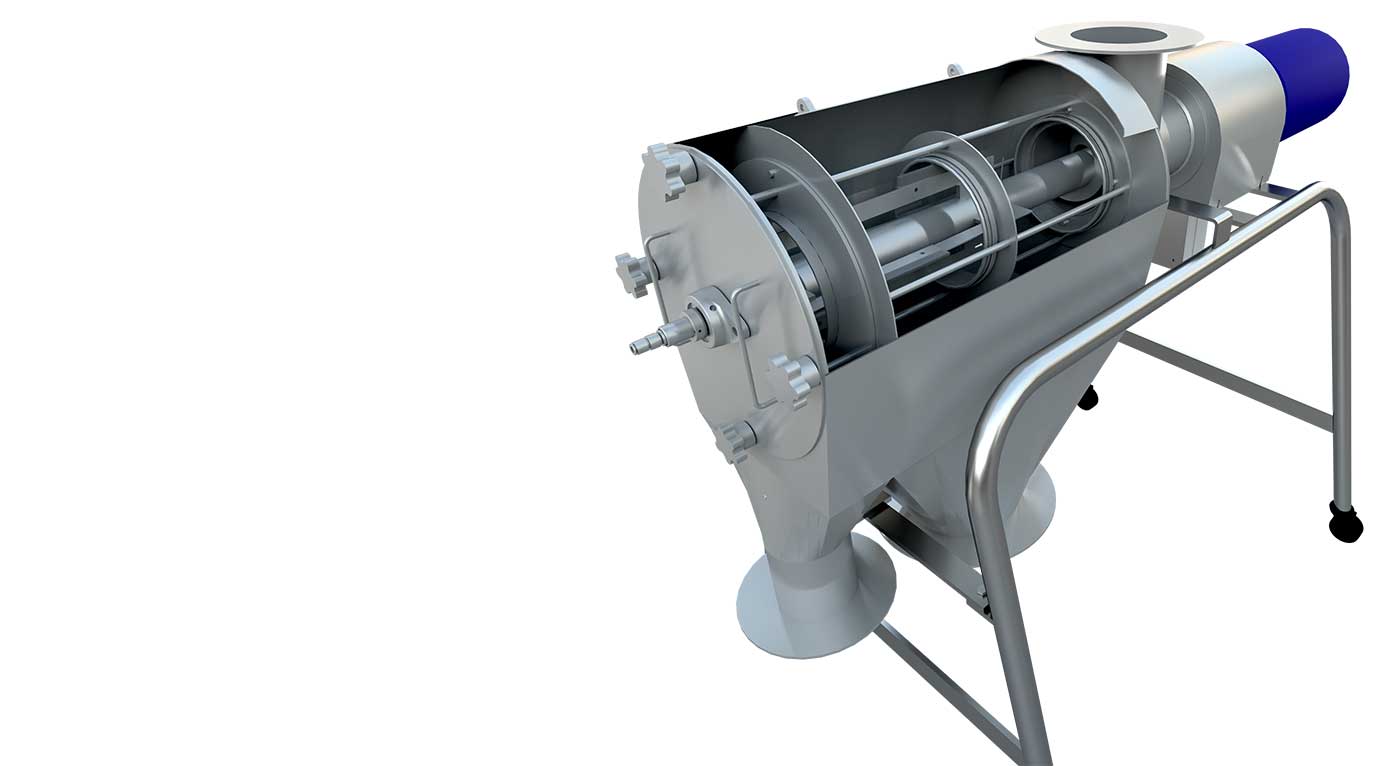

After listing & understanding the problem, our Sales Engineer suggested to install Sivtek® Roto Sifter as it will serve solution to both the problems: Material Loss & Noisy environment.

Roto Sifter also is widely known as Centrifugal Sifter works on centrifugal force principal & it’s working helped lumps to break inside the screen. The roto sifter has a shaft with blades (peddles) that keeps on rotating inside & due rotation of blades the lumps break inside only. Lumps once break becomes powder again is screened during the process.

This helped them to minimize the material loss to a great extent.

One more advantage of Sivtek® Roto Sifter is its noise free operation. The Roto Sifter generates minimal noise which is even less than 40DB.

Results

After listing & understanding the problem, our Sales Engineer suggested to install Sivtek® Roto Sifter as it will serve solution to both the problems: Material Loss & Noisy environment.

Roto Sifter also is widely known as Centrifugal Sifter works on centrifugal force principal & it’s working helped lumps to break inside the screen. The roto sifter has a shaft with blades (peddles) that keeps on rotating inside & due rotation of blades the lumps break inside only. Lumps once break becomes powder again is screened during the process.

This helped them to minimize the material loss to a great extent.

One more advantage of Sivtek® Roto Sifter is its noise free operation. The Roto Sifter generates minimal noise which is even less than 40DB.