Success Story – TAPIOCA STARCH & MAIZE STARCH

Overview

One of India’s biggest tapioca starch & maize starch manufacturers from South India was looking for efficient check screening & sieving solutions with higher output for both products.

Having meet our National sales head in one expo, the Production engineer of the company contacted him for the solution.

Requirement & Challenges

During the interaction, the Production Engineer of the company said, “Currently we are using conventional round Vibro sifters, but we are having multiple issues & problems”

Below are the highlighters of the concerns they were facing with round Vibro sifters

- Not able to achieve efficient screening due to mesh chocking which also resulted in frequent mesh tearing.

- They were not able to gain desired output due to inefficiency & poor performance of the round Vibro separators.

- The absence of a closed system created dusting & also injected airborne contaminations into the starch. They were looking for totally enclosed sieving system.

- Round Vibro Sifter demanded high maintenance & was also generating a high noise level.

- One of the main concerns was material handling. The oversized starch must be resent for processing to make it fine, but the currently there was absence of handling oversize material & they had to manually transfer the oversized starch for reprocessing. This increased their labor cost & operational cost as well.

- They were also facing problem of removing mesh for cleaning and maintenance as the mesh changing system was quite complex & time-consuming.

After briefly analyzing the problems, our National sales head along with regional sales manager decided to visit the plant to provide tailored solution as per the layout of their plant.

Solution

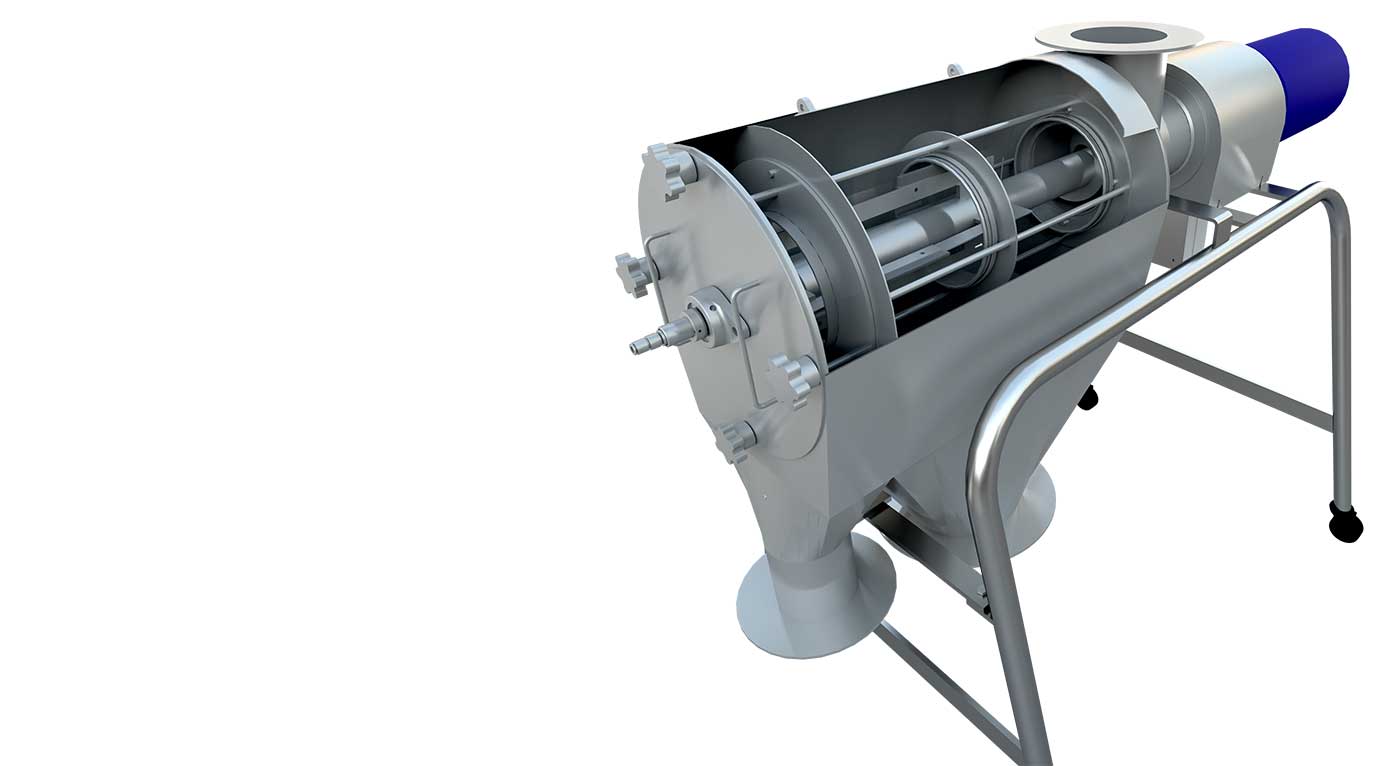

After visiting the plant & studying the problems, experts from Sivtek suggested a customized solution which included the installation of 2 nos. of Sivtek® Twin Roto Sifter & 1 no. of Sivtek® Roto Sifter with screw conveyers for transferring oversized starch for reprocessing.

Roto sifter with screw conveyer was installed with the purpose to solve their multiple problems.

First, the screening efficiency was up to the mark due to the working principle. The Roto Sifter works on the centrifugal force which enabled them to achieve efficient & precise check screening.

Due to proper calculation & efficiency in working of Roto Sifters, they were easily able to get the desired throughput.

Problems of dusting & airborne contamination were also eradicated as Sivtek Roto Sifter enables totally enclosed screening operation. (Dust-free operation)

The problem of high noise level was also solved as Roto Sifter operates vibration free at a noise level less than 80DB.

Results

Their main concern of (material handling) transferring oversized starch for reprocessing was solved by connecting material outlets of Roto Sifters with Screw Conveyor. The screw conveyer enabled the automatic transfer of oversized material directly for reprocessing.

One more reason to install Sivtek Twin Roto Sifters & Sivtek Roto sifter was its “easy to remove mesh system” for cleaning it. The internals of sifters can be easily removed without any tools as it is powered with knobs at the end of the system. This helps in easy & quick cleaning.

Installation of customized engineered solution of twin roto sifters & roto sifters with screw conveyer served solution to their all concerns & production engineer of the company provided the following feedback.

“We are delighted with Galaxy Sivtek’s approach of providing the solution that was beyond their limitations. The sales head visiting the plant and suggesting the customized solution of centrifugal sifters with screw conveyer in itself shows their pleasant attitude toward serving their clients. Overall, we are extremely satisfied with the solution as every single problem we were facing was solved.”