Machine

Enhancers

Bead Blast Finish

Brush Finish

MILD STEEL PAINT

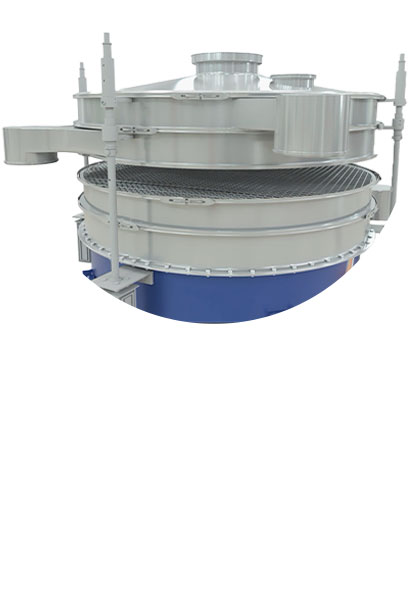

Machine

Finish

To cater the wide range of applications, industries, and customer requirements, four different types of finishes are available, such as mirror finish, bead blast finish, brush finish, and paint. Finishes like these can be used on a wide range of materials such as powders, granules, liquid or slurries.

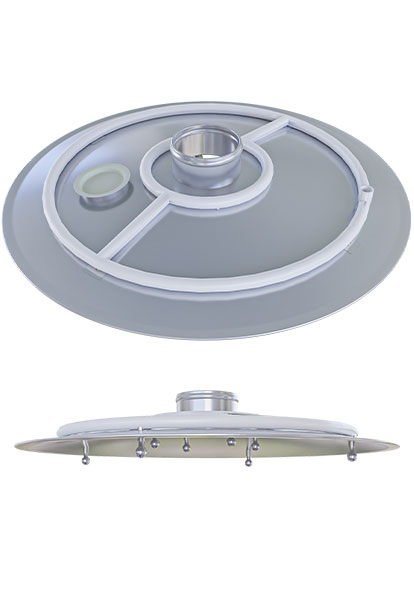

Mesh Deblinding Kit

ULTRASONIC SIVTEK

SIVTEK OTLAC

Clean In Place

Capacity

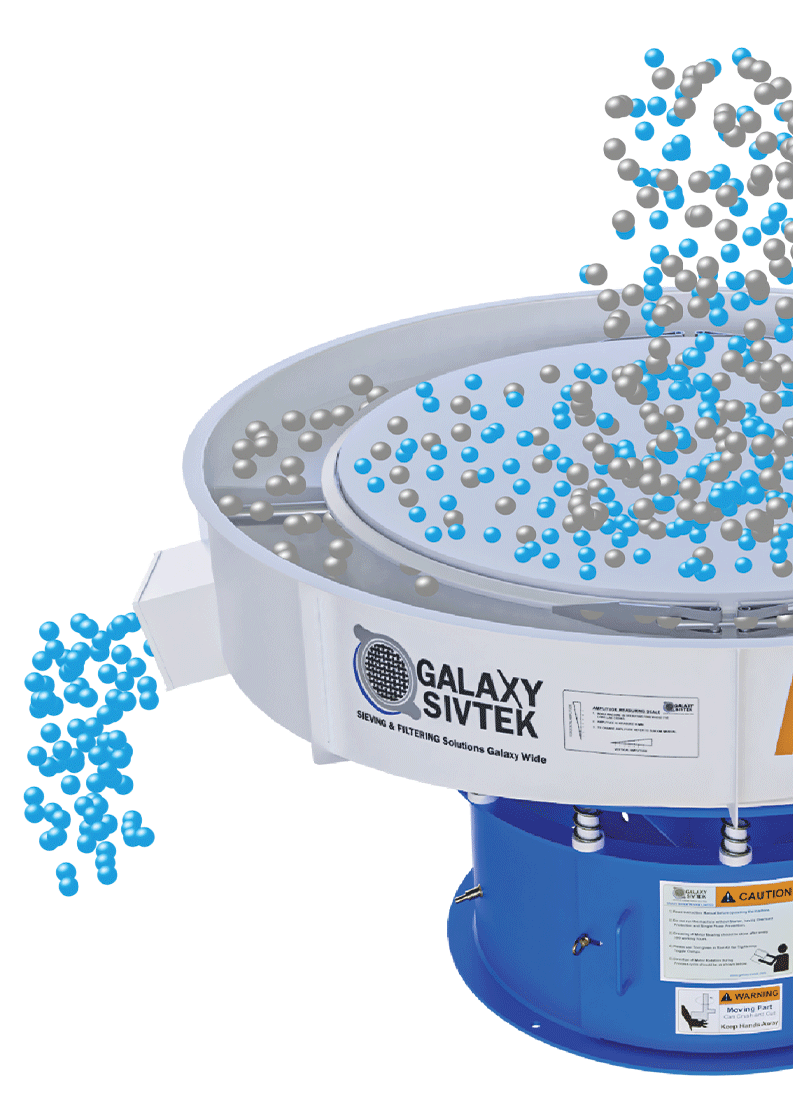

Enhancers

In addition to our machines, there are multiple capacity enhancements available, such as Mesh Deblinding Kits, Maximizer decks, Rotary Brush Cleaning Systems, etc. These features can improve the throughput capacity, efficiency, mesh life etc.

HOPPER

SCREW CONVEYOR

BUCKET ELEVATOR

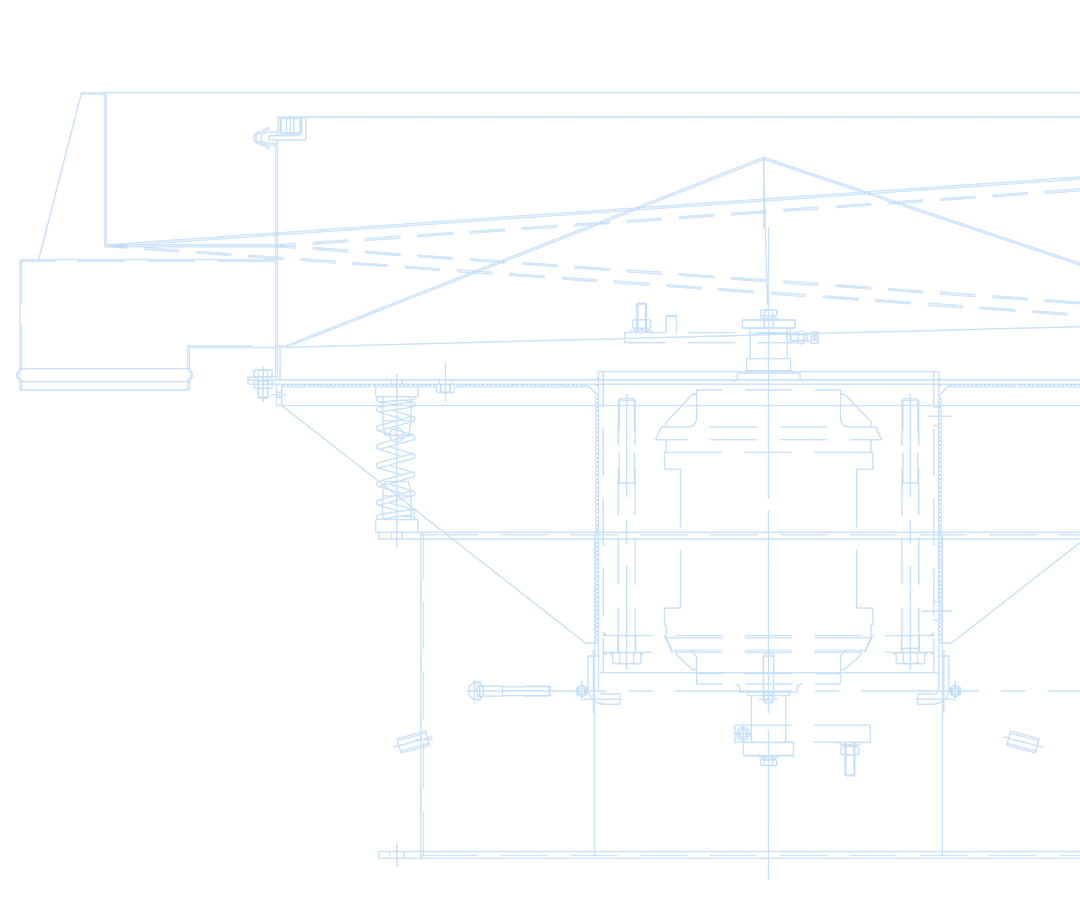

Material

Handing System

Based on years of experience in handling bulk materials for various industries which includes Screw Conveyors and Powder Transfer Systems, bag dump station etc. These solutions help to maintain hygienic standards and transferring and packing material become easier.

DECK LIFTING ARRANGMENTS

ANTI VIBRATION MOUNT

AUTOMATIC LUBRICATOR

VALUE

ADDED EQUIPMENT

We are dealing with different accessories such as Pneumatic deck lifting mechanism, anti-vibration mounts, automatic lubricator, etc. These accessories can help the users to operate the machine with ease and more effectively and reduced manual work and increase machine’s life also.

MAGNETIC GRILL

BFM FITTINGS

BELLOW & SLEEVE

Machine

Addons

To Improve the hygienic standards in final material’s quality we provide various types of safety check measures like the magnetic grills, magnetic belt separator, etc. and we also suggest few addons like BFM fittings, rubber bellow to transfer the material from one machine to another to maintain hygiene and prevent external contamination.