Committed To Quality, Committed To You

Over the course of our company’s journey, a lot of our screening and filtering machines have performed beyond expectations and helped numerous companies enhance their screening process. However, the one machine that stands out for its excellent performance is the centrifugal sifter. Its ingenious design and fine mesh screens help you screen the finest materials and easily delumps and deagglomerate the screening material efficiently.

But, even with such great a machine, there rise some challenges. While screening abrasive, sticky, or very fine particles, they tend to clog up the screens and rotary blades which can drastically reduce your efficiency of screening and make it burdensome.

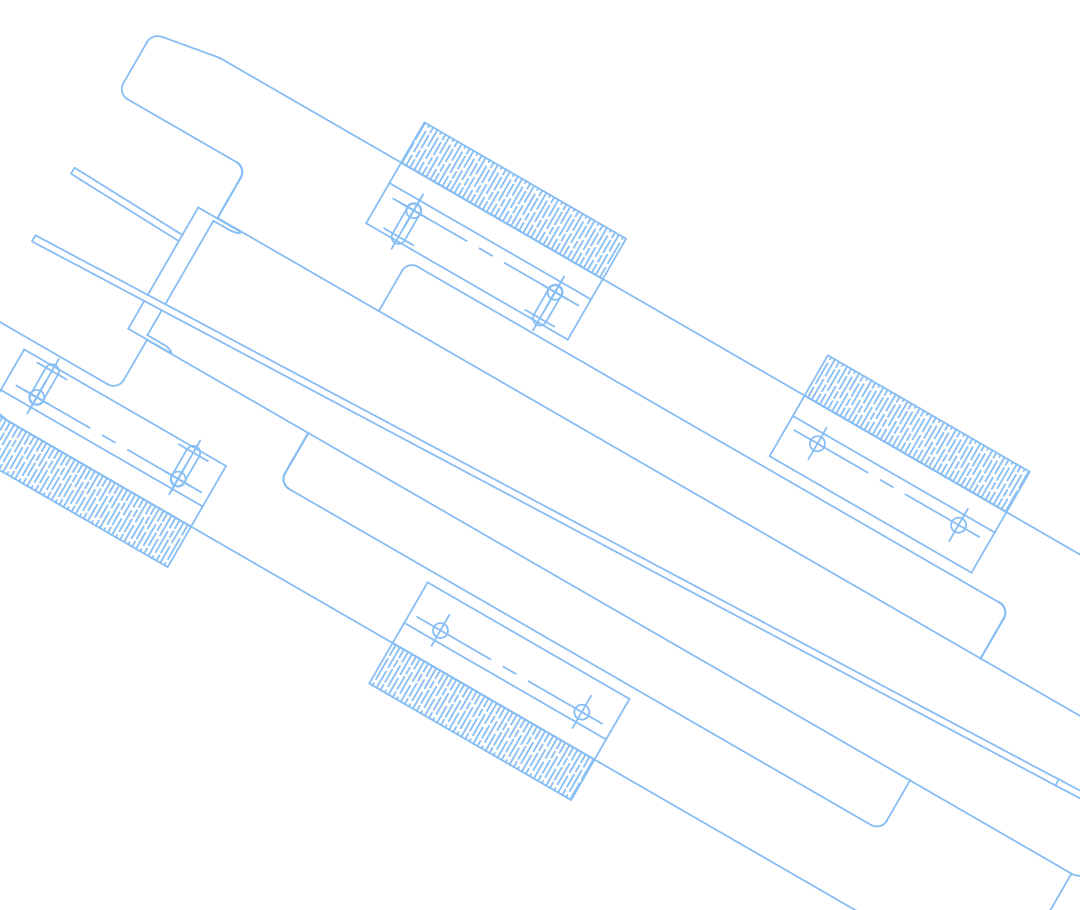

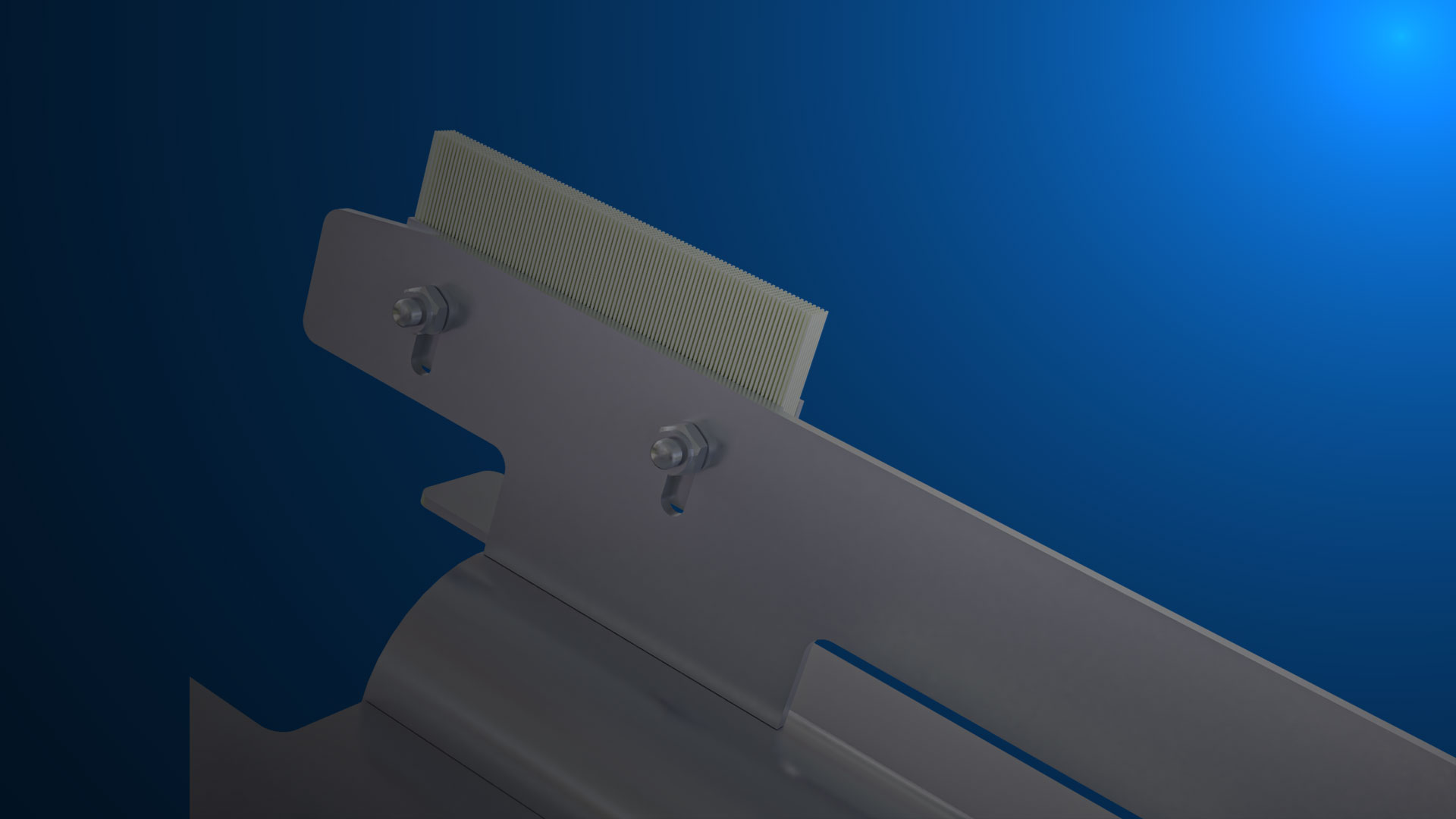

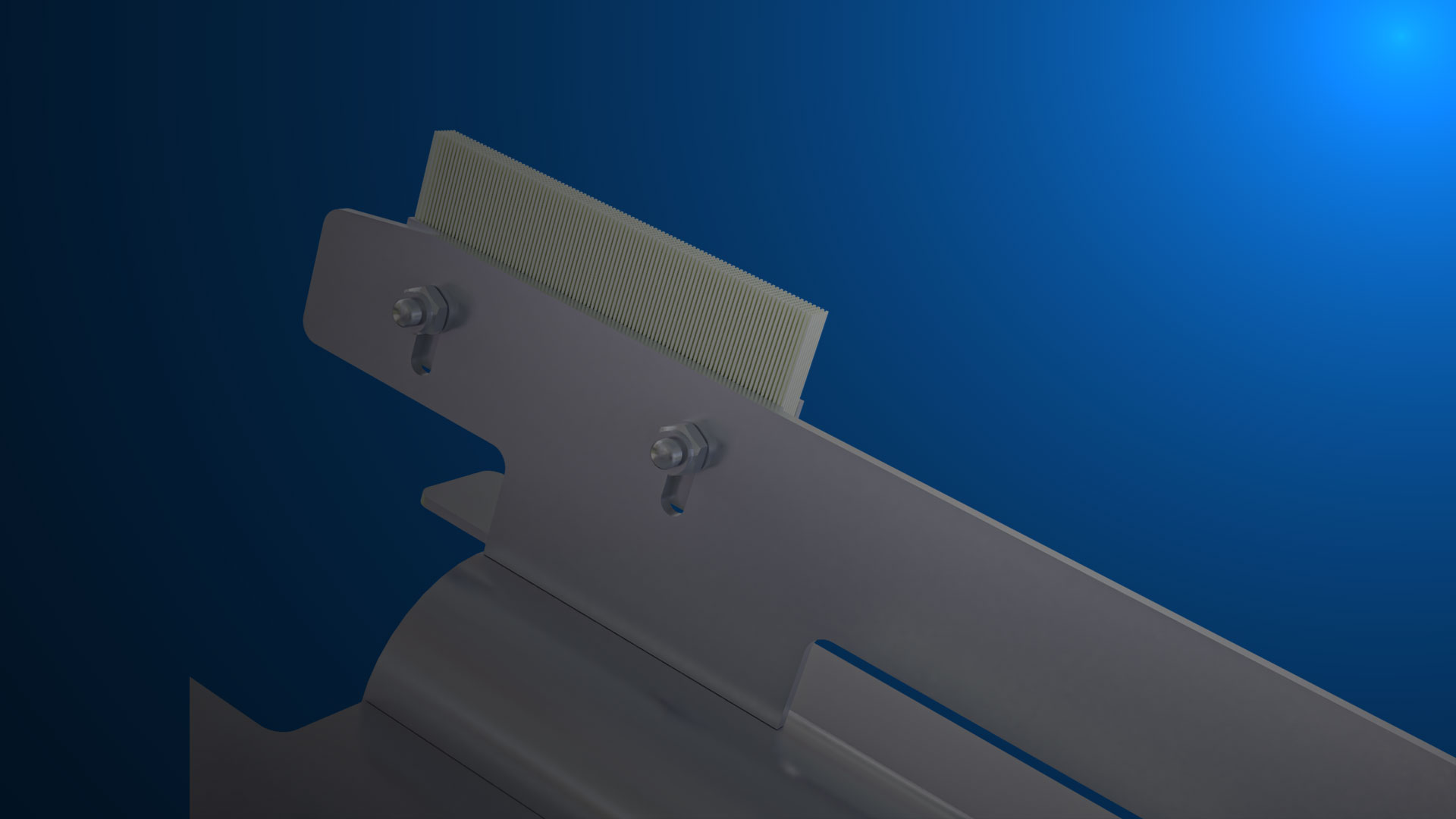

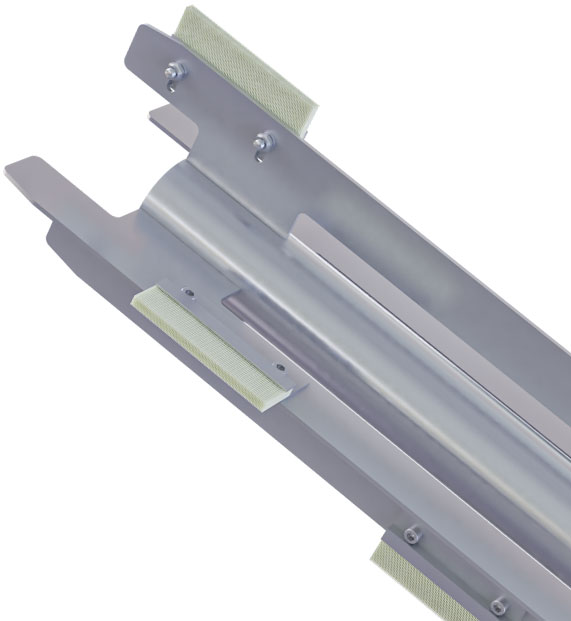

To help you deal with such situations, we bring you our special deblinding with brush add-on. This amazing device helps you keep your screens clean and efficiently removes any material that is stuck on the inner rim of the centrifugal sifter. They are also very helpful in breaking down huge lumps that can get accumulated in the screening materials.

What makes this brush blade add-on so revolutionary is that it helps you preserve the quality and integrity of the screening material which assures a purer and refined end product. Also, it makes your screening process way quicker, as you won’t have to deal with de-clogging your sifters every now and then.

Our brush blade deblinders have been revolutionary for a lot of companies who were able to increase their throughput and quality of their material with this add-on. It has also helped them reduce their production cost as they don’t have to spend a lot of money on cleaning and maintaining the screening machine.

The sifters on our centrifugal screeners are designed in a manner that you can easily add or remove the brush blade add-on. You don’t need to change the mechanism of the machine nor need to replace any major parts. All they do is allow you to adapt better to the screening material and provide the most optimal screening performance.

To make sure that your screening material stays safe and hygienic until the end, our rubber blades are made with materials that are approved by FDA & CGMP.

The de-blinding rubber blades can very easily scrap the fibrous materials from your centrifugal sifters and break lumps that might form in the screening materials.

Due to the brush blade’s versatile applications, the de-blinding brush blades are beneficial for a wide range of industries, including food processing, metal, and chemicals.

While making sure that the quality of your screening material does not get compromised, the brush blades help you to increase your throughput drastically and makes your screening process efficient.