Committed To Quality, Committed To You

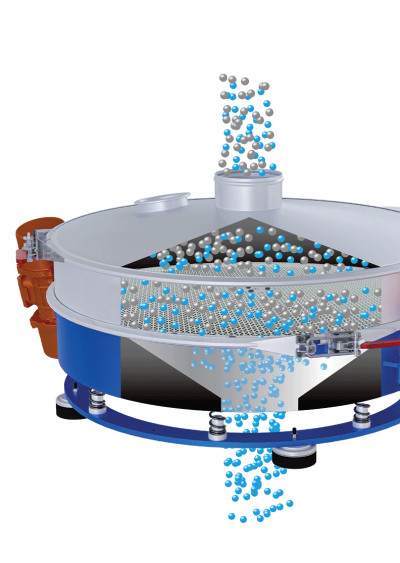

As the bottom outlet of the machine is placed directly underneath the top inlet, the Inline Sivtek Dual Motor allows you to reduce the minimum height requirements of the machine and make it more compact. The two imbalance weight gravity motors that are mounted on the machine create a 3D motion which allows the material to churn in a circular motion and increase the throughput. Another great thing about its mechanism is that the inlets and outlets of this dual-motor separator can be customized to fit your established piping infrastructure.

The dual-motor design of the machine generates vertical, as well as horizontal vibrations which maximize the flow-through of the material.

By the inlet and material discharge outlet being installed in the centerline, the inline sifter reduces the movement of the screening material which significantly reduces the screening time.

The compact body of the Inline Sivtek, accompanied by the castor wheels, is highly mobile and easy to manoeuvre.

Because of the centerline inlet and outlet design, the inline sifter reduces the movement of screening material and provides higher output compared to conventional machines.

Powered by two motors, the Inline Sivtek Dual Motor can generate higher vibrations and provide better performance.

The Inline Sivtek is highly manoeuvrable due to the castor wheels which reduces the number of hands required for its operation.