Committed To Quality, Committed To You

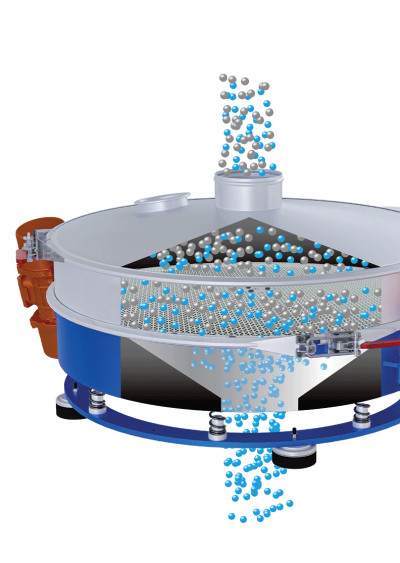

With the help of two imbalance weight gravity motors that are mounted on the machine, the Inline Sivtek Dual Motor separator reduces the minimum height requirement of your machine. This also enables the bottom outlet to be placed directly under the top inlet. Furthermore, the dual motors that are mounted on both sides of the machine create a 3-D motion that allows maximum flow-thru. The Inlets and Outlets of Inline Sivtek can be custom designed as per your existing equipment and piping infrastructure.

The Inline Sivtek has a compact design that provides low profile and can be easily incorporated into the processing line.

By the inlet and material discharge outlet being installed in the centerline, the inline sifter reduces the movement of the screening material which significantly reduces the screening time.

The compact body of the Inline Sivtek, accompanied by the castor wheels, is highly mobile and easy to manoeuvre.

The robust and state-of-the-art design of Inline Sivtek makes it capable of functioning seamlessly while using lesser power, which can highly reduce your costs.

The Inline Sivtek is highly manoeuvrable due to the castor wheels and compact size, which reduces the number of hands required for its operation.

With the easy mesh changing clamps that are embedded in the machine, you can very conveniently clean the screener and assure pure raw material every time.