Committed To Quality, Committed To You

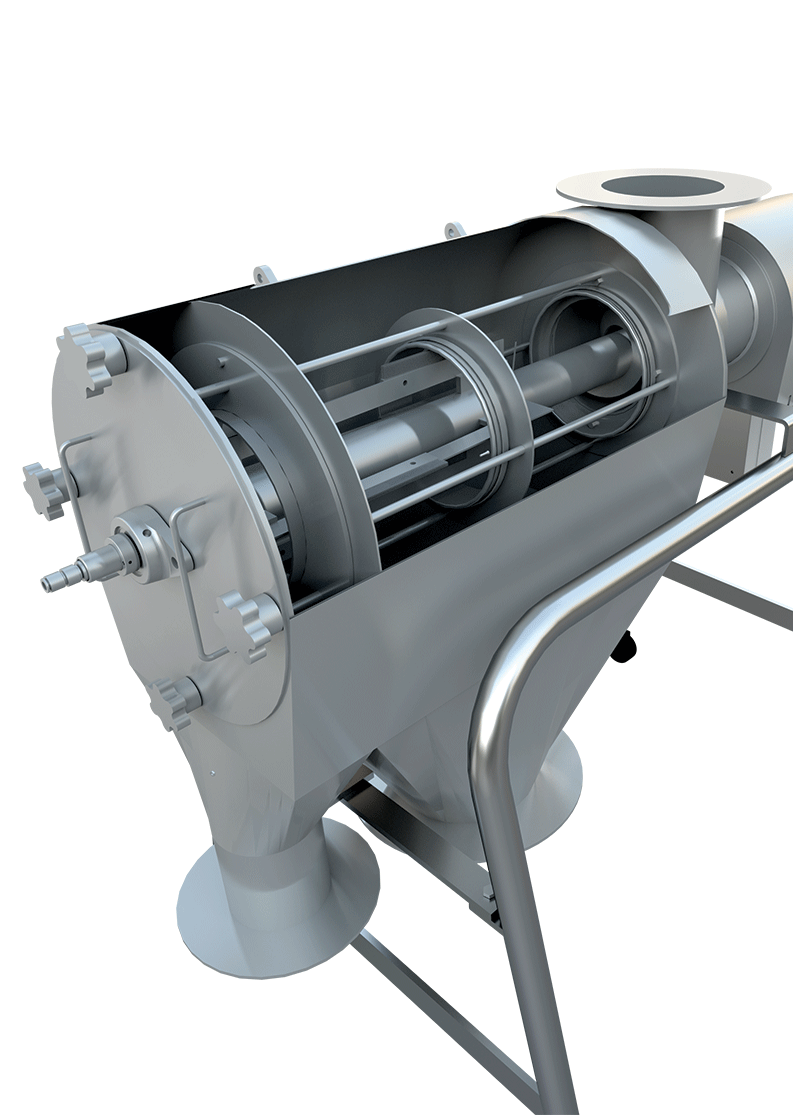

The pneumatic roto sifter combines centrifugal force and air conveying to separate particles efficiently. Material enters the sifting chamber, where a spinning mesh screen sorts particles by size—fine through the mesh, larger particles out. This method ensures precise separation and a dust-free operation in a compact, easy-to-integrate design, optimizing both product quality and processing efficiency.

Optimized to handle low bulk density products, ensuring thorough screening without compromising on speed or quality.

Fully enclosed processing environment prevents dust escape and contamination, providing a cleaner, safer workspace.

Allows for easy adjustments to accommodate different product types and sizes, ensuring versatility across various applications.

Ensures consistent particle size and purity by effectively removing unwanted materials and fine particles from low-density products.

The closed environment reduces the risk of dust emissions, enhancing workplace safety and maintaining high hygiene standards.

Its efficient design and operation lead to reduced waste, lower labor costs, and minimal maintenance requirements, contributing to overall cost savings.