Committed To Quality, Committed To You

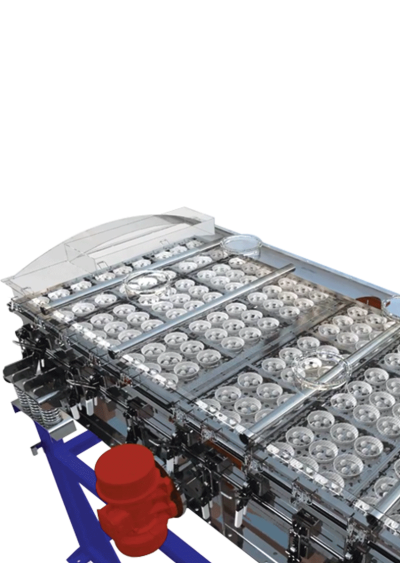

The most ingenious aspect of Sivtek Rectangular Separator®’s design is the placement of the dual motors. Being attached at the rear end of the screening deck, the two motors allow you to produce synchronized vibrations that generate exciting forces on the screen. This makes the particles move in a straight line, as the stacking forces act perpendicularly to the motor shafts. When these exciting forces are combined with the self-gravity of the material, the machine through the screening material upwards in a linear motion on the screen surface.

The Sivtek Rectangular Separator® is designed to process heavy-duty screening materials and generate higher output than any conventional machine.

Sivtek Rectangular Separator® also allows you to adjust the power distribution according to your required production conditions.

The machine is tightly enclosed, which prohibits the screening material from overflowing or any other particles from entering the machine. It is 100% contamination-free.

With the accurate gradation results, preserving the material from contamination ensures that the product remains in its optimum quality.

The Sivtek Rectangular Separator® provides optimum and higher quality output in comparison with any other conventional screening machine.

With most of the processes being automated and longer-lasting wear parts, it is considerably easier to maintain and clean this machine.