Committed To Quality, Committed To You

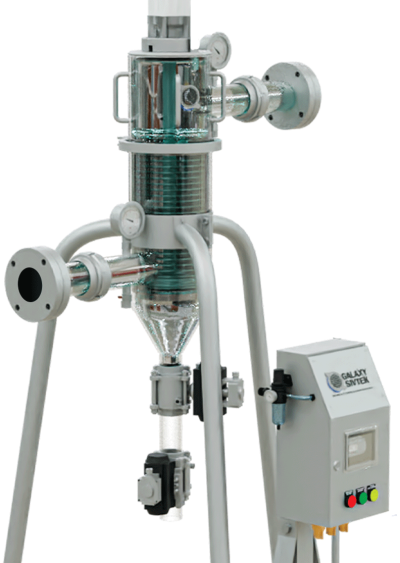

The Sivtek self-cleaning filter® works on the principle of the ΔP, i.e., the differential pressure of the inlet and the outlet, where the material flows from the higher-pressure zone to the lower pressure zone. Here the material is collected on the outer periphery of the backet, and with the help of the disc cleaning arrangement that material is collected in the bottom chamber of the flushed out at regular intervals.

Where conventional filters require periodic cleaning after every batch, our automatic filters are powered by pneumatic actuators that are installed with a cleaning disk.

The self-cleaning filter comes with a cleaning disk that accumulates the particles and residues from the periphery of the basket.

Sivtek Self Cleaning Filters can withstand the filtration of liquids that are as hot as 250℃

The filters provide the finest level of screening, and the cleaning disk assures to keep the filters clean.

The ‘Plug and Play Function’ of the machine automatically controls cylinder strokes which rotates the cleaning disk and removes the contaminants on the filter.

The most impressive property of our product is the 24X7 capacity to continuously process the substance without taking a break.