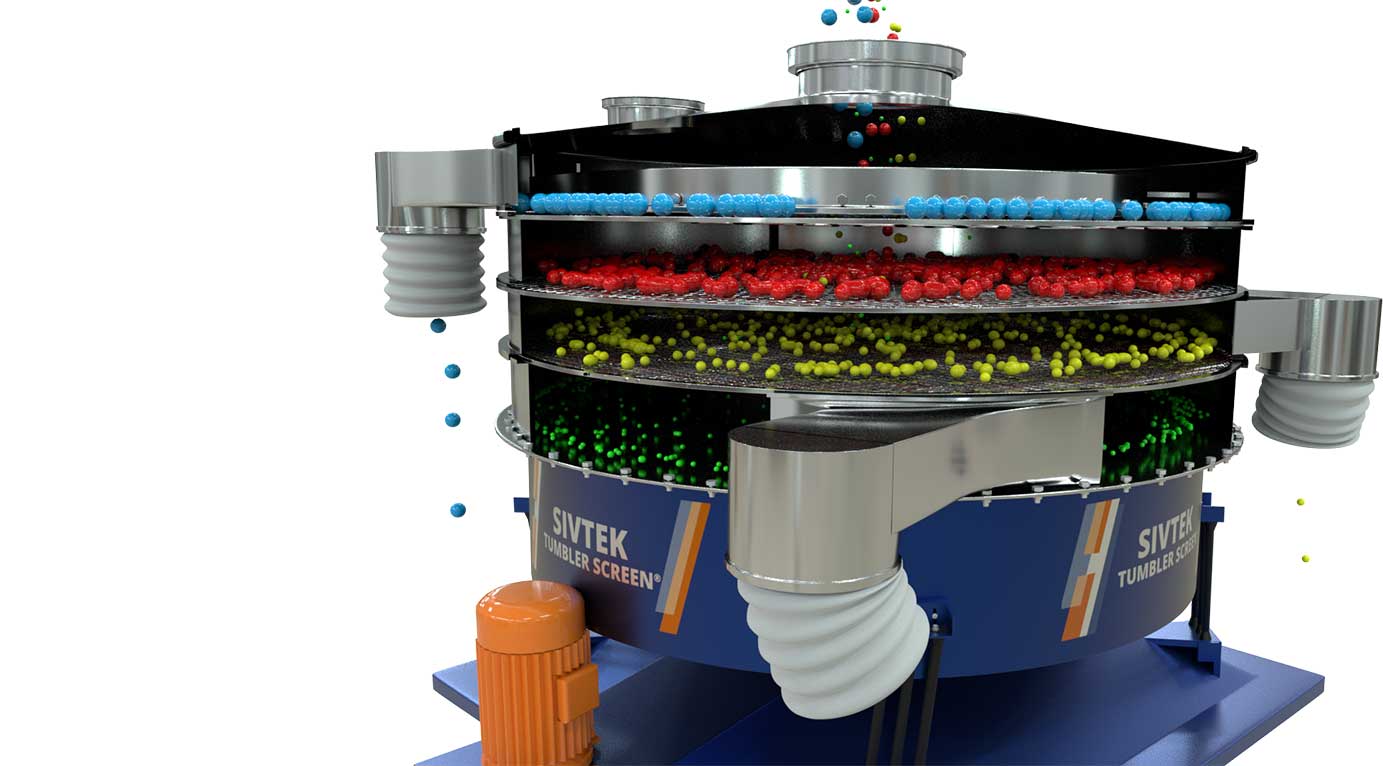

Sivtek Tumbler Screen® for efficiently screening Den Soda

Overview

Sivtek Tumbler Screen® was installed by replacing the conventional vibro separator to achieve 90-95% efficiency while grading & de-dusting Den Soda.

Our client was a prime manufacturer of den soda with clientele like Unilevr and P&G. They supplied den soda to Unilevr & other companies as den soda is the major raw material for manufacturing detergents & soaps. The client was looking for grading & de-dusting den soda efficiently with an output of 8-9 tons/hour.

Requirement & Challenges

Currently the client is using a conventional round Vibro separator with two decks for grading & de-dusting den soda but are facing many concerns including major concern about output & proper gradation.

Production head of the company, in conversation with our product expert, said, “We are using a round Vibro separator, but there are serval challenges. It would be great if you can send any of your product experts to examine how we can overcome those challenges.”

Mr. Mayank Patel (Sr. Manager – R&D) visited the plant along with a team member.

During the visit, our technical team understood their real-time concerns. Low output, frequent maintenance & cleaning, more manpower & more power consumption were the main issues.

Among the requirements, the most important were capacity & output. With the current conventional Vibro separator they were getting 1.5 tons/hour, but their requirement was of 8-9 tons/hour.

Round Vibro separator called for more maintenance as it generates vibration & due to vibration more wear & tear takes place. More maintenance & frequent cleaning were also countable concerns.

The client was looking for a grading machine that would have more life span, less maintenance & easy to operate.

Solution

After understanding concerns & requirements, our technical team decided to conduct a trial on client premises with SIVTEK Tumbler Screen®

A successful on-client premises trial was conducted to evaluate results & to reach the conclusion. With Sivtek Tumbler Screen® 90-95% efficiency was achieved.

The three-dimensional elliptical movement helped to achieve accurate gradation of Den Soda with nearby 8 tons/hour throughput.

After a trial, the brief report was sent to the production head with a suggestion to install Sivtek Tumbler Screen® with a pneumatic deck lifting system. The client analyzed the report & agreed to the suggested solution.

Results

The result was up to the expectations as the client ordered 1 more unit of deck 72” Sivtek Vibro Separator®.

Sivtek tumbler Screen® generates three-dimensional tumbling motion, unlike conventional round sifters that generate vibration. Due to the absence of vibration, there is minimal wear & tear, less maintenance & long life span.

Three-dimensional elliptical movement helps in perfect gradation. The radical inclination makes den soda move from center to outwards & tangential inclination makes it move in a circular pattern; thus, an accurate gradation is achieved with ease.

We had powered our Tumbler screening machine with a pneumatic deck lifting system & that made life easy for the operators.

Previously for changing or cleaning the screen operators had to open the clamps, remove the deck, change or clean the screen & again attach the deck; but, with the pneumatic deck lifting system, they have to just remove the clamps & press a button to lift the deck.

Sivtek Tumbler Screen® was also proved to be a more economical option as compared to a conventional Vibro separator. Tumbler demanded minimal maintenance & works with standard motor, while Vibro separator demanded more maintenance & it works with vibrating motor. The power consumed by a standard motor is almost 5 times less than the power consumed by a vibrating motor.