Success Story: Screen Detergent Ingredients & Powder.

Overview

Industrial Vibro Sifters & Safety Screener from Galaxy Sivtek have Increased Detergent Powder Quality & Production Capacity.-Fortune 500 FMCG Company.

Requirement & Challenges

Business Case: Screen Detergent Ingredients & Safety Screening of Detergent Powder.

Scenario: There are primarily 3 processes in the manufacturing of detergent powder spray drying, agglomeration, dry mixing, or combinations of these processes.

Right Quality. The typical production process includes, the dry ingredients (raw materials) procured from different sources being mixed with liquid ingredients during the manufacturing of detergent powder.

The homogeneous mixture is thoroughly mixed in a plow shear mixer to eliminate lump formation due to liquid/moist ingredients and finally, the detergent granules/powder is packaged in the right size.

Challenge: The respective production teams at detergent manufacturing units found detergent ingredients to be of low quality due to the presence of stones, grit, paper cuts, threads, and lumps after procuring raw materials from different vendors.

Also, previously the operating costs were very high as regular Vibro Sifters were used before the final packing. It occupied more space and time to assemble-disassemble which impacted the production throughput of the manufacturing unit due to high downtime.

Concerns:

Quality of Detergent Ingredients(Pre-Mixing)

Quality of Final Product (Before Packaging).

Solution

The production heads at fortune 500 detergent manufacturing companies cited that, during the pre-mixing stage the dry raw materials procured from various vendors consist of foreign particles that affected the quality of the detergent powder. Also, the detergent manufacturers found agglomerated granules or uneven particle size of detergent powder/granules after the plow mixing stage, impacting the final product quality, concludes, National Sales Manager, Galaxy Sivtek India.

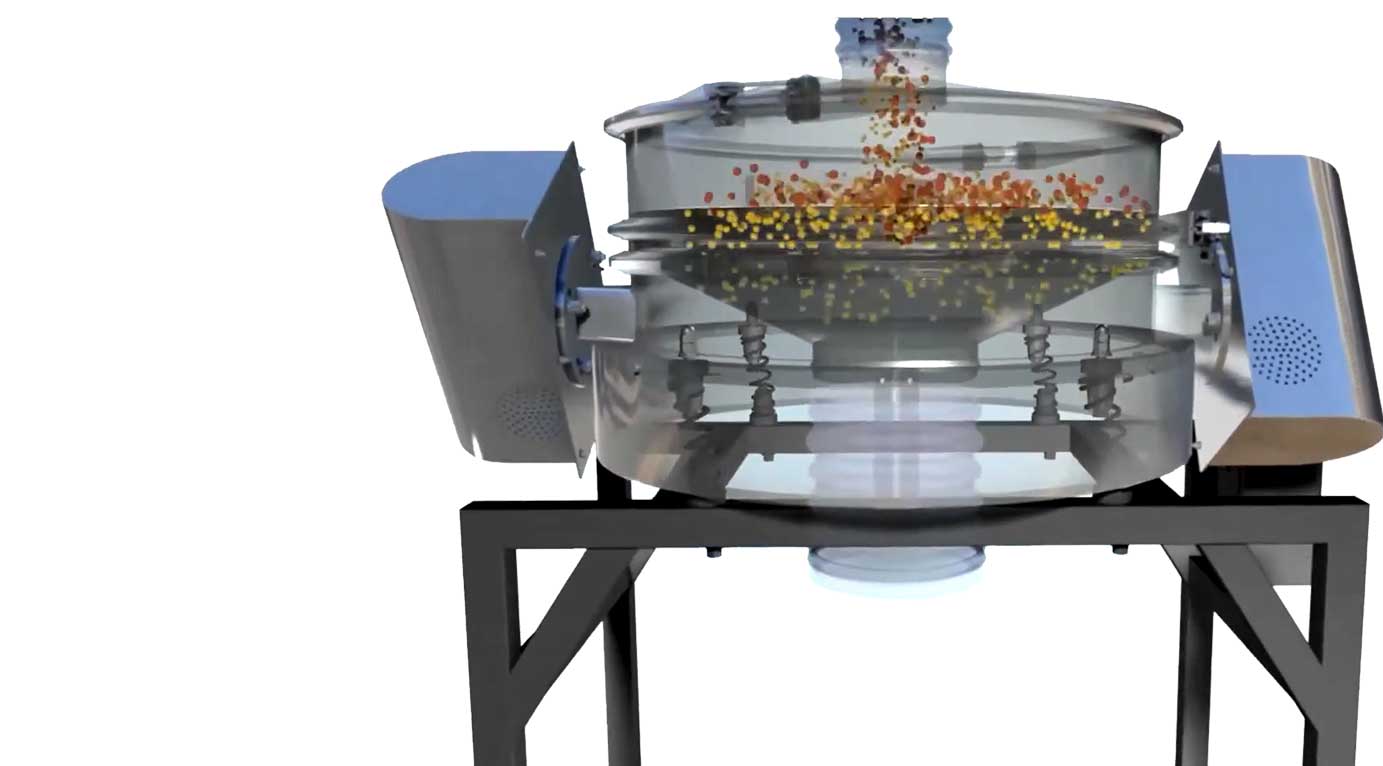

After understanding the detergent manufacturing lines and production concerns at fortune 500 companies, Galaxy Sivtek identified and proposed SIVTEK Screening & Filtering Solution to achieve the right quality of detergent powder and production throughput.

Results

The engineering team at fortune 500 detergent brands was completely satisfied with the technical aspects of the SIVTEK Vibro Separator and installed SIVTEK Vibro Sifter to screen the detergent ingredients such as STP, Sodium sulfate, etc to achieve the right quality of ingredients before mixing with liquid ingredients.

As a typical production process of detergent manufacturing, the high-quality dry ingredients were mixed with liquid ingredients such as enzymes, perfumes, brighteners, artificial dyes and colors, and other additives in a plow shear mixer to achieve a consistently high-quality batch of a homogeneous mixture of detergent powder.

The detergent mixture is thoroughly mixed in a plow mixer to prevent lump formation due to liquid/moist ingredients. Once the detergent powder is mixed meticulously the global detergent manufacturers installed SIVTEK Inline Check Sieve according to their screening requirement at the final stage of the production line to safety screening of detergent powder to ensure product quality before the final packing of detergent powder.

The compact i.e. low headroom and sanitary design of the SIVTEK Safety Screener assisted the leading detergent brands to decrease the operating costs without compromising on the production flow rates as the SIVTEK Check Screener neatly fits into current production lines.