Committed To Quality, Committed To You

Quality is what everyone craves! All the industries desire to make high-quality products so that the brand reputation is maintained. From Chocolate manufacturers to paint producers and syrup companies to multinational food factories, every Industry in the world is using filters in the form of cartridge filters, bag filters, strainers, and other different industrial filters.

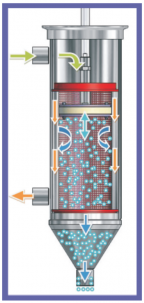

Galaxy Sivtek’s Self Cleaning Filter is the most popular and trusted industrial filter nowadays. A self-Cleaning Filter provides a number of advantages over conventional filters. Let’s see some of the benefits which can ease the manufacturing processes.

The name itself clarifies that the main advantage of this filter is to clean itself automatically. There is a mechanical piston that moves along the periphery of the trapezoidal-shaped basket to remove oversize particles.

Those industries that are using the above conventional filters are facing the problem of cleaning the filter at some interval of time because the basket gets chocked and production must halt for that period.

Self-Cleaning Filter eliminates the replacement of filter media because you can use the same filter basket for a longer period and no need to worry about disposable cartridges.

This filter collects the oversize material in a purging chamber and automatic actuator valves allow the release of oversized material through the pipe between two valves.

Self Cleaning Filter has a unique design that can easily fit into the existing processing line and work efficiently without any breakdown. It is also known as an inline filter because of its compact design & continuous flow of the liquid material.

The design of this filter can replace the conventional filters and can be connected easily to the processing unit.

The Filter Control System allows you to set the system one time & be free then after. This will allows the operator to adjust the timing of piston and actuator valves.

Timings of both the mechanism depends on the material, process & pressure applied in the filter. This will reduce the involvement of the operator and monitor the processing.

The filter not only automats the process but also provides high-quality effective filtration which contains zero impurity. This filter is equipped with a high-quality trapezoidal-shaped basket that can handle 10-bar differential pressure.

Cough Syrup, liquid cocoa, paint, or detergent! This filter can serve the purpose of purity with hundreds of liquid materials & provide optimum results.

The filter is designed to run continuously day & night without any interruption. Its self-cleaning property enables a smooth & continuous process along with eliminating the need for manpower for cleaning it after every batch.

It’s a unique design, that makes the filter robust equipment to remove unwanted impurities, and improves the material quality. Self Cleaning Filter is capable to filter thousands of liters in a day giving high efficiency.