Overview

The chocolate industry in India has experienced significant growth in recent years, driven by increasing consumer demand for high-quality and premium chocolate products. According to a report by Research and Markets, the Indian chocolate market is expected to grow at a compound annual growth rate of over 11% between 2021 and 2026.

Various organizations have started processing the plants for chocolate industry and the old ones have expanded their business like the one we have supplied our 6 customized machines for screening and filtering of liquid chocolate.

The customer primarily caters to the processing of chocolates and other cocoa related products, for the same they were looking for numerous customizations and performance parameters, which only Galaxy Sivtek could offer.

Are you interested in customized solution?

Contact Us Now: Customized Screening Solution for Chocolate ProductionAbout the product:

Liquid chocolate is a type of chocolate that is in liquid form and is used as a coating or filling for various food products such as cakes, pastries, and biscuits. It is also used in hot chocolate drinks and as a dip for fruits, nuts, and other snacks.

The process of making liquid chocolate involves several steps. The cocoa beans are first roasted and ground to make cocoa liquor. The cocoa liquor is then mixed with sugar, milk powder, and other ingredients to form a chocolate paste. This paste is then further refined to achieve a smooth and consistent texture.

The refined chocolate paste is then mixed with cocoa butter and heated to a temperature of around 60-70°C to create a liquid chocolate. The heating process is important to ensure that the chocolate has a smooth texture and is free from lumps. The liquid chocolate is then cooled to a temperature of around 40-45°C, which is the optimal temperature for coating or filling food products.

Requirement & Challenges

The customer was facing challenges with the screening and filtering of the liquid chocolate in their current layout. They were also facing issues with handling the liquid chocolate as it is a very tricky substance as its changing state as soon as the temperature around it changes, they needed solution for this also to maintain the liquid state of the chocolate to make it more flowable.

The second hurdle that the customer was facing of the inspection window which should be able to inspect also when required would be able to check on the wire mesh and conduct the process of cleaning and replacement of wire mesh, for this process they had a space constraint.

The third challenge they were facing was collecting of the screened chocolate and transferring it for further process, which no one could solve.

Solution

The client was looking for multiple solutions for the problems faced by then with respect to the production line integration, handling liquid chocolate at precise temperature, and transfer of chocolate. The team from Galaxy Sivtek visit the production plant on various occasions in Andra pradesh examined the situation there and had multi-level discussions.

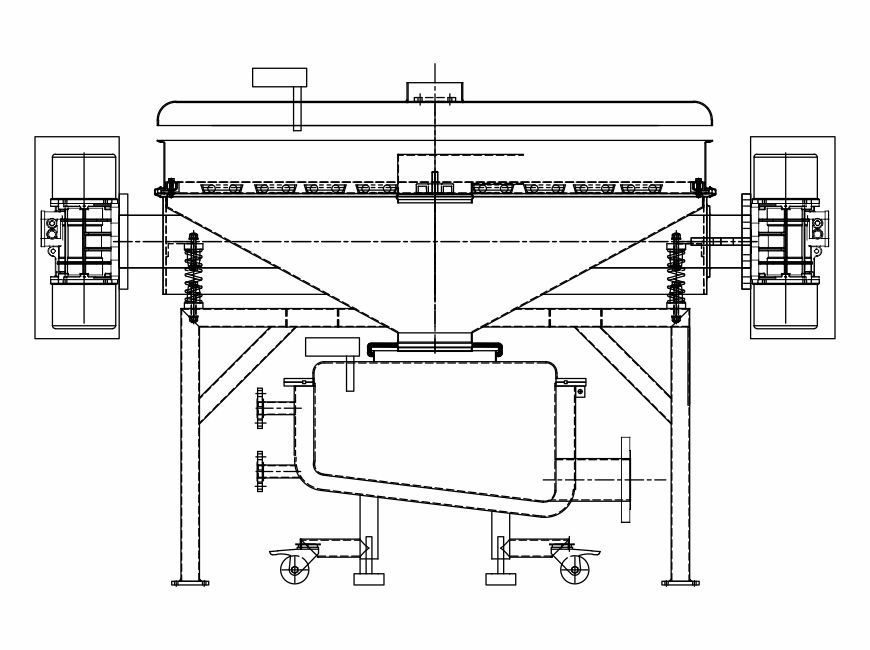

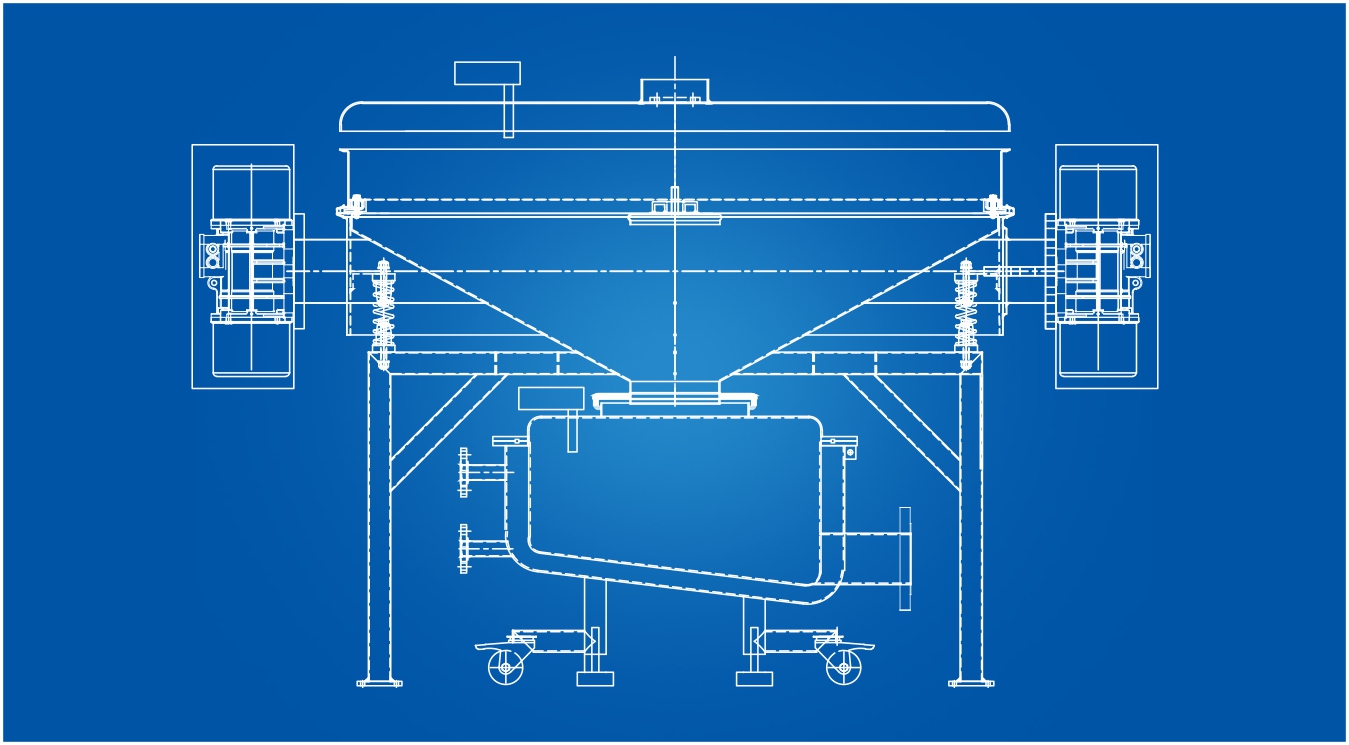

They finally came to a conclusion that the suitable machines for the process would be the Inline Dual motor with 60 inch diameter, the problem of integrating the machines into the current production line was achieved with the help of a specially designed rotating lid assembly, which not only helped in integration but also solved the issue of mesh inspection and replacing it when required.

A special sensor was also installed at the overhead transfer container to protect the mesh screen against heavy load of material, being dumped for screening process.

Screening chocolate can be a very tricky process especially when treating liquid chocolate, and no one can understand the plight more than Galaxy Sivtek that is why we have specially developed temperature controlled collection chamber with hot water jacketing which does not allow the liquid chocolate to harden.

Results

As a result of the efforts, the customer has achieved improved output, with all the 6 machines and the customized solutions offered are functioning like clockwork without any issues. We have supplied all the necessary spares and equipment required for further functioning of the equipment. With decades of experience dealing with the chocolate industry we have supplied our various machines for chocolate processing irrespective of dry or wet application. Please feel free to contact us for your requirements.