Galaxy Sivtek R&D and design team developed a special customised solution for one of India’s biggest food and beverage processing start-up, facing issue with labour, time and cost.

Client’s profile:

The company is the biggest producer and supplier of organic farming, processing, and distributing. The company is not just an organic producer it is also into environment conversation and sustainable development of the fields and development of Indian farming society.

Challenge:

The engineering team of the company reached out to the experts from Galaxy Sivtek for their sieving and filtering solutions, there were various problem which the client was concerned with.

Primary concern that they were facing was of labour manually carrying and feeding the flour bags into the screening machine, which was taking a lot of time and was also not cost effective, it also possessed a health hazard as the accidents could happen while carrying it manually.

There was also a issue that came us of conveying and dumping the material onto the vibro screen. Which was also done manually, causing the issue of irregular flow rates, and altering outputs.

To maintain the quality of the product and remove all the ferrous contaminants there was also a requirement of a solution. Which with careful examination by the experts came to a conclusion.

Are you interested in customized solution?

Contact Us Now: Screening With Material Handling SystemWith so many challenges and requirements form the customer, the design and R&D team had to visit the processing plant in Madhya Pradesh, the technical director explained the entire process flow of the system to the team, and demanded the solution in a short period of time.

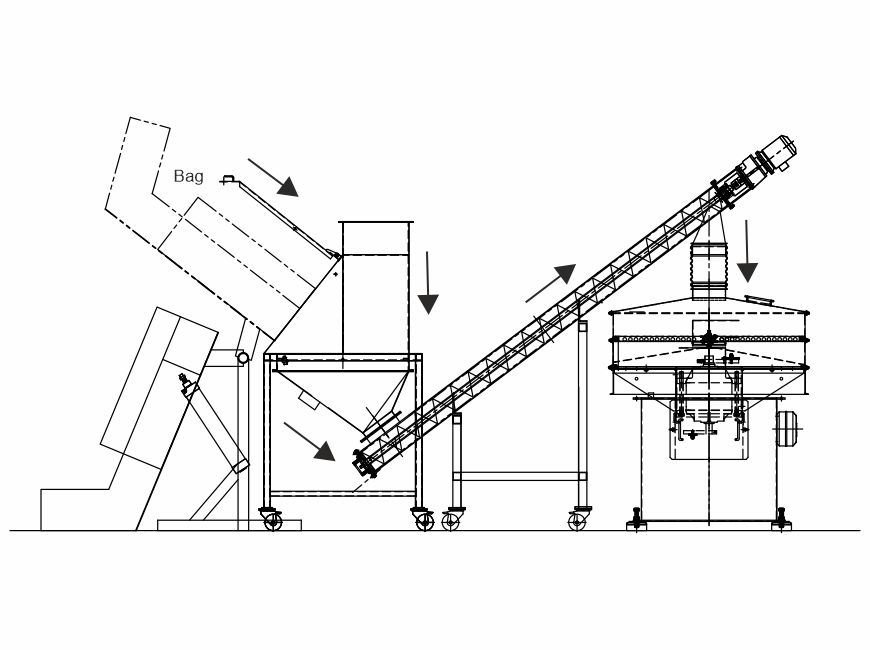

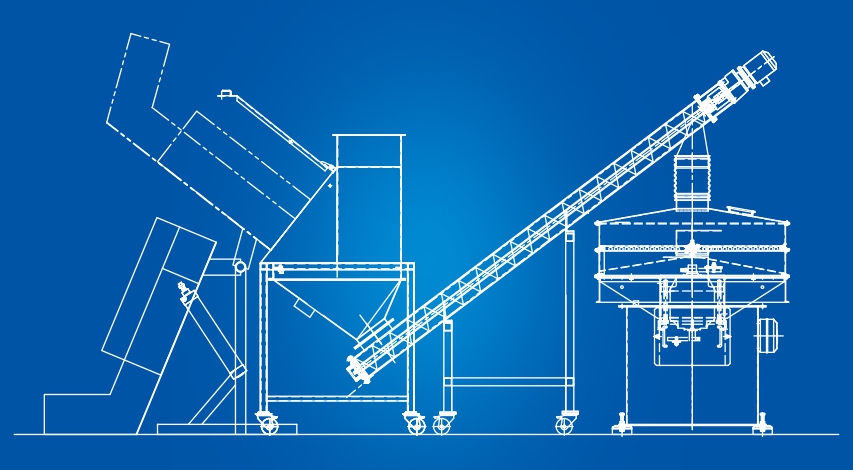

By step by step encountering the problem the design team came up with a solution of a pneumatic bag tilter, which was capable of lifting weights up to 70kgs and dropping it off at the bag dump station, where a set of 2 pneumatic ball vibrators for tapping the hopper mechanism and not letting the material to be accumulated.

The second concern was for material handling and transferring it from one location to another, this solution was provided by designing a screw conveyor, which transferred the material from the hopper of the bag dump station to the vibro screen for sieving.

Here there were two levels of gradation provided for over size and undersize particles. For consistent screening and increased strength of the mesh screen, a sandwich screen ring is provided. For the final check on the material and ferrous contaminants, a magnetic grill is provided at the output of the material.

Result:

The customized solution provided not just helped them to achieve the desired output but also helped to solve the main issues of picking up the bag and dumping it onto the dumping station, also the material conveying system helped for a uniform material flow and less product loss.